Plywood

Plywood is a versatile, cost-effective, and readily available building material. Harbor Exports carries various plywood grades for all your construction needs, from panels and sheathing to just about any building supply you can think of.

What is Plywood Made of?

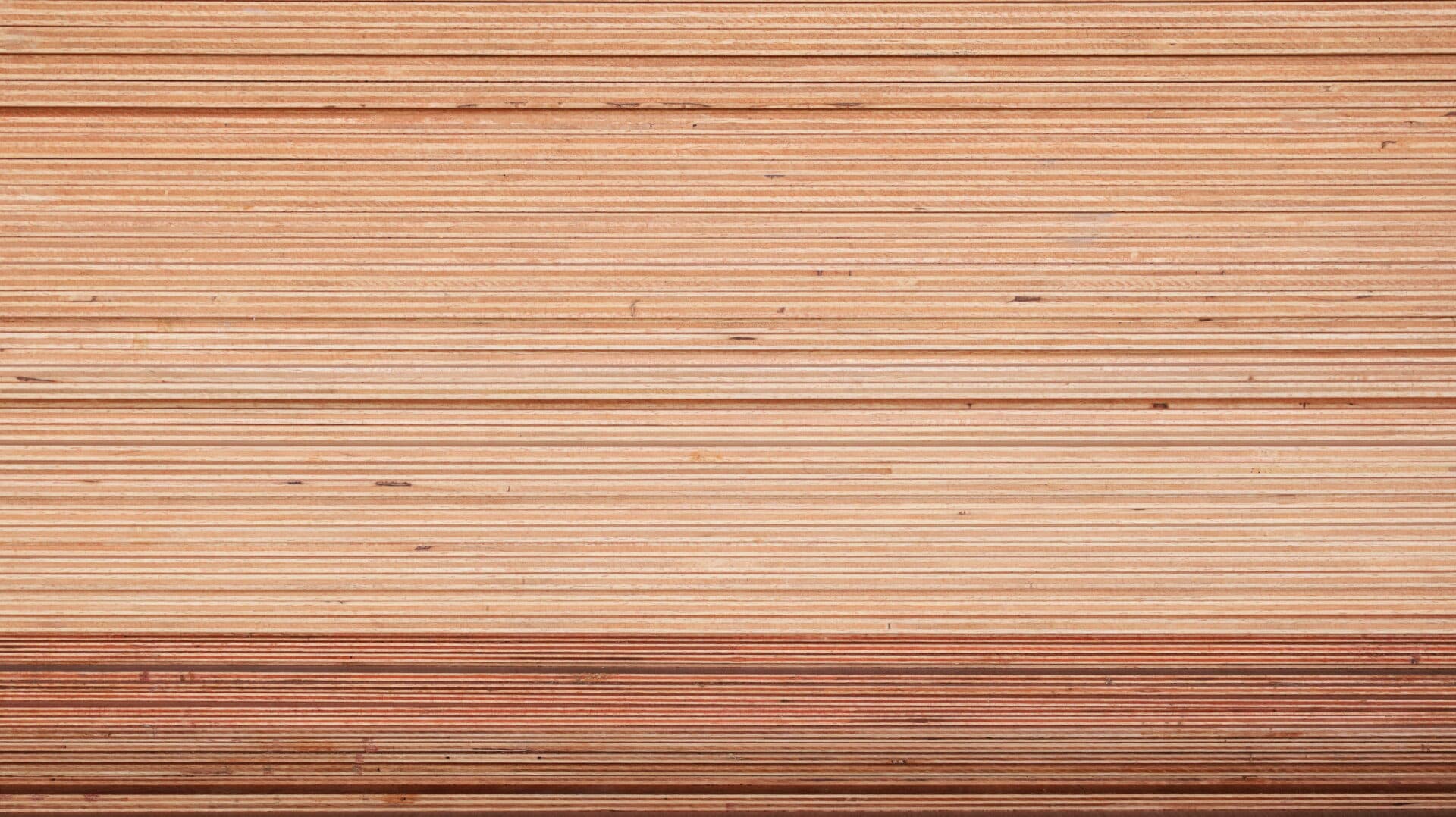

You may have used plywood extensively before but not realized how it’s made. Plywood is a composite made of thin sheets of wood veneer, or “ply,” joined with adjacent layers that are cross-laminated and glued together in a perpendicular fashion. It has a consistent appearance since it is manufactured from whole layers of logs instead of strands.

It’s an engineered wood type from the manufactured board family that includes medium-density fiberboard (MDF), oriented strand board (OSB), or particleboard (chipboard). All plywoods contain resin and wood fiber sheets to produce composites.

Plywood Grades and Sizes

Plywood grades indicate the quality and appearance of the veneers, while sizes refer to the standard dimensions of the panels. Plywood is graded based on the quality and appearance of the face and back veneers:

- Grade A is the highest-quality veneer, free of knots, splits, and repairs. It is recommended for clear finishes and exposed surfaces.

- Grade B: Solid surface with minor repairs, tight knots, and slight discoloration. It is used for painted finishes and semi-exposed surfaces.

- Grade C: Knots, discoloration, and repairs are allowed. This grade is best for concealed applications or where appearance is not critical.

- Grade D: This is the lowest-quality veneer with knots, splits, and repairs. It is suitable for structural applications where appearance is not essential.

Plywood panels are often designated with a two-letter grade, such as AB, BC, or CD, indicating the quality of the face and back veneers, respectively. For example, AB plywood has an A-grade face and a B-grade back for applications where only one side will be visible.

Standard Plywood Sizes

Plywood is available in various standard sizes to accommodate different project requirements. The most common size is a 4×8 foot sheet, which is 48 inches wide and 96 inches long; standard sizes range from 24″ x 24″ up to 60″ x 60″. We also supply pre-cut “handy” panels for smaller projects or when a full sheet is unnecessary.

Plywood Thickness Options

Plywood thickness is another important consideration when selecting the right panel for your project. Thickness is typically expressed in inches or millimeters and can range from 1/8 to 1-1/4 inches.

Plywood vs. OSB

When it comes to building materials, plywood is often compared to other engineered wood products like OSB or MDF. Plywood and OSB are structural panels and share many strength and performance characteristics, but they’re made differently.

Instead of thin layers of wood veneer cross-laminated and bonded together as in the plywood manufacturing process, OSB is made from wood strands arranged in cross-oriented layers and compressed with heat-cured adhesives.

OSB vs. Plywood: Which is Better?

Both OSB and plywood have advantages and disadvantages, so one isn’t necessarily superior to the other.

OSB can be made into much larger panels than plywood, is more uniform, and is generally considered inexpensive. It’s also eco-friendly since it can be made from smaller-diameter trees that are farmed (e.g., poplars). Plywood requires larger trees from old-growth forests.

Plywood, however, has quite a few benefits:

Cost

Like OSB, plywood is a highly cost-effective building material.

Less Off-gassing

Both plywood and OSB off-gas formaldehyde, but OSB off-gasses more of it. Regardless, you can store both wood products outside for a few weeks to get rid of the gasses for safety.

Lighter Weight

Plywood is lighter than OSB. One 23/32-inch, 4×8-foot piece of plywood is 67 pounds, and the same dimension piece of OSB is 78 pounds. This makes plywood easier to install.

Minimal Swelling

Swelling is less of an issue with plywood than OSB due to OSB’s manufacturing process. Plywood generally returns to its normal thickness as it dries, while OSB can remain swollen.

Strong Foundation

Plywood floors are 10% stiffer than OSB ones, so you get less squeaking, cracking of hard floor surfaces, and spongy flooring. Also, nails and screws usually stay put better in plywood.

Retains Less Water

Plywood retains less water than OSB and fights deterioration better as a result.

What is T1-11 Plywood?

T1-11 siding is a wood-based exterior siding commonly used in residential construction for outdoor structures. It is made from plywood or OSB and has vertical grooves cut into its surface at regular intervals, typically 4 inches or 8 inches apart. These grooves give it a textured appearance and help to mimic the look of traditional wood siding panels.

T1-11 siding is popular for its durability, affordability, and ease of installation. It is often used on sheds, barns, and other rustic-style buildings but can also be found on houses, especially in rural or suburban areas.

Order Plywood Products From Harbor Exports

As innovators and industry disruptors who supply products to builders and contractors globally, we know you want to build a deck, dock, or construction project that is both functional and beautiful. Harbor Exports offers many products to lead the industry with everything you need for your construction needs.

Construction Supply Imports Made Easy

Questions about supplies? Ready for a quote? Give us a call or send us an email and a member of our team will reach out to you immediately. Our customer service is as superior as our supplies.